The Minamata convention entered into force the domestic calcium carbide PVC industry

sourceBusiness

publisherJennifer

time2017/09/12

- The Minamata convention entered into force the domestic calcium carbide PVC industry

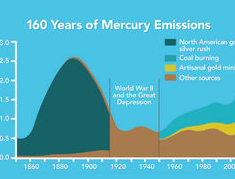

In August 16th, the "Minamata Convention on mercury" (referred to as the "Minamata Convention") formally implemented. As one of the contracting parties, our country will strictly limit the use of mercury. Calcium carbide production of polyvinyl chloride (PVC) is a big mercury consumption, and China's calcium carbide production of PVC accounted for 80% of the country's total production capacity of PVC. With the promotion of the implementation process, the PVC industry reshuffle soon.

1, the Ministry of environmental protection issued a performance schedule

From the signing of the implementation of the "Minamata Convention" landing lasted 4 years. In October 2013, representatives of 92 countries and regions Chinese, signed the "Minamata Convention"; in August 2016, China became the thirtieth batch of china.

For the "Minamata Convention", the environmental protection department of environmental protection deputy director of foreign cooperation center Yu Lifeng in the July regular press conference that the Ministry of environmental protection has been carried out a lot of preparatory work, including in conjunction with the relevant departments issued a number of amendments involving mercury emission standards, the assessment of the 10 involving mercury industry, launched a national strategy and action plan making work etc..

According to the requirements of the Convention and the preliminary assessment, the ministry gives the performance schedule, by 2020, the elimination of mercury containing batteries, fluorescent lamp does not apply for exemption from Tim mercury products production and import and export, stop the mercury thermometer and manometer of import and export, PVC monomer unit product to achieve the use of mercury amount less than 50% in 2010; in the atmosphere of coal-fired power plants and other emission sources, 2020 will be the initial completion of emissions inventory control, a clear focus on the sources, establish emission reduction targets and measures; in 2032, shutting down all the original mercury mining.

The field of mercury involving China mainly includes chlor alkali industry, calcium carbide method, PVC, primary mercury ore, mercury containing electric light source, etc.. The production of PVC mainly by calcium carbide and ethylene by two kinds of methods, the main raw material calcium carbide carbide is the main raw material, coal, crude salt, ethylene is oil.

International ethylene production of PVC, and the status quo of China's oil resources, rich in coal, less gas determines the domestic production of calcium carbide PVC dominant. Mercuric chloride - activated carbon catalyst required for carbide method is the main source of mercury pollution in the process of the production of PVC industry, this process is the "Minamata Convention" key governance related to mercury industry.

2, the implementation of low mercury production PVC is difficult

In the process of industrial production of caustic soda and polyvinyl chloride, a great deal of mercury, waste acid and waste mercury catalyst are produced, and mercury consumption accounts for 85% of the total domestic mercury consumption every year, resulting in about 17 thousand tons of waste mercury catalyst." Ministry of environmental protection science and technology standards division director Zou Shoumin said.

In September 1, 2016, China implemented the revised standard for the discharge of industrial pollutants from caustic soda and polyvinyl chloride, and increased the emission control requirements of 10 types of atmospheric pollutants, including mercury and its compounds, vinyl chloride and two dichloroethane. Under the new standards, total mercury emissions will be reduced by 67%.

High mercury catalyst mercuric chloride content used carbide method was 10.5%~12%, catalyst consumption is about 1.2 kg / ton. Low mercury catalyst mercuric chloride content at the national promotion for the use of 4%~6.5%, low mercury catalyst to replace the high mercury catalyst can make unit PVC products with mercury to reduce the amount of 50% is the key way for China to cut mercury in the "13th Five-Year" period.

In fact, as early as January 19, 2011, the Ministry of environmental protection issued a "notice" on mercury pollution prevention to strengthen the production of PVC by calcium carbide and related industries, since 60 days after the announcement, new construction, renovation and expansion of PVC by calcium carbide production project must use low mercury catalyst. The existing calcium carbide process PVC production plant can not be rebuilt or expanded before the low mercury catalyst is used to replace the high mercury catalyst, and gradually reduce the production of the high mercury catalyst, and completely eliminate the high mercury catalyst by the end of 2015.

However, up to now, the calcium carbide process, PVC enterprises, low mercury catalyst utilization rate of less than 50%. The Ministry of environmental protection and environmental protection cooperation center senior expert Sun Yangzhao said in an interview, low mercury catalyst is difficult to spread, partly because of the high mercury catalyst of the traditional route of mature and stable, and the use of low mercury catalyst in the process need to run, enterprises are worried that economic benefits are affected. On the other hand, low mercury catalyst product quality standards, the market is chaos, enterprises use high mercury catalyst, and even the use of waste mercury catalyst and high mercury catalyst mixed as low mercury catalyst sales, damage the interests of the enterprise, disturb the market.

3 PVC industry Linkao

The "Minamata Convention" to eliminate the use of mercury or mercury compounds in chlor alkali production before 2025 for States parties, at the same time to 2020, PVC monomer production per unit of mercury quantity is reduced by 50% than in 2010.

Not only is the "Minamata Convention" the implementation process will continue, and China's mercury ore resources are decreasing, many old mines have been failure, China carbide process PVC enterprises have to have to change it.

Specifically how to limit mercury, ban mercury real landing, rather than an armchair discussion, is currently the industry's most concerned about the problem, which is also related to the use of high mercury catalyst production PVC enterprise life and death. Many companies do not replace production capacity, or use low mercury catalyst, in the final analysis, or the cost increase, affecting the enterprise efficiency." Calcium carbide method PVC production enterprise relevant person in charge said.

He believes that the state should formulate and implement preferential policies, to actively adopt low mercury catalyst, mercury free catalyst technology roadmap for policy incentives and financial support. In the development of non mercury catalyst on the technical route, state and local governments should also increase the support, in order to achieve low mercury free production.

Some experts suggest that China's PVC overcapacity, there are a lot of production and production capacity limit, for new production capacity, the state should take tough measures to control the calcium carbide PVC production